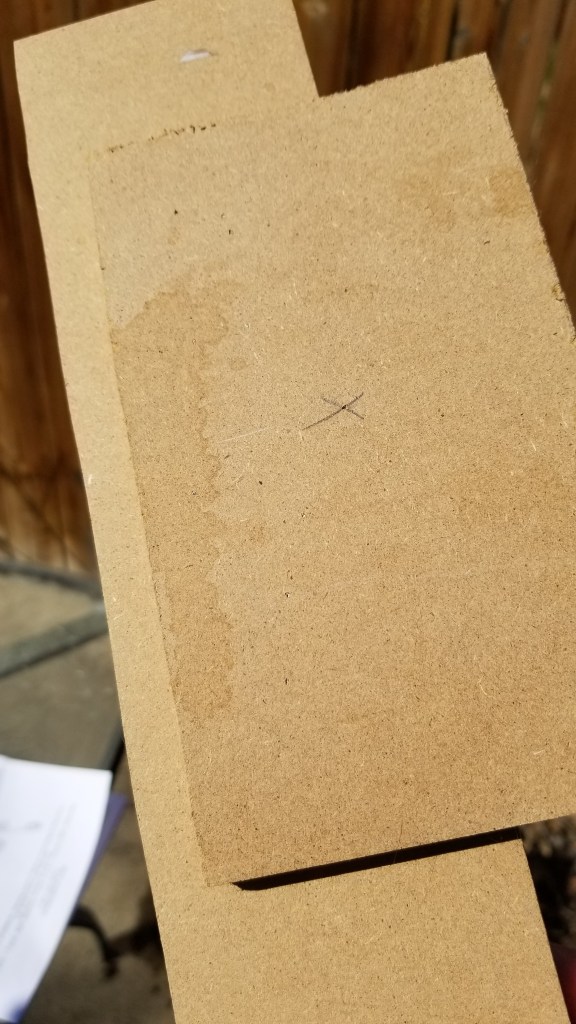

Over the past few days I’ve been working on the support structure for the MIP. The pilot’s side and the middle section is mostly done at this point. The first officer side will be a bit longer because I decided to modify the design a bit. I’m planning on making it easily separable from the rest of the panels. This will make transportation easier down the road.

I also made the decision to buy the MIP itself from homecockpits.fr. Its a bit of a complex piece and they can do a better quality and likely quicker job than I could with this piece. The parts came to a total of €495.00 or $685.58 CAD. Not exactly cheap but hopefully worth the price! It is made to order and will be customized with my aircraft registration and SELCAL. C-FOLF will live! (I’m just not sure when) :p

I’m heading back to work soon, but if I have time I may start working on the pedestal. I’m excited to see that take shape. I can put my real airbus door control panel in it right away!